Taking Full Advantage Of Equipment Long Life: Buying Costs Undercarriage Parts Solutions

Taking Full Advantage Of Equipment Long Life: Buying Costs Undercarriage Parts Solutions

Blog Article

Make Best Use Of Efficiency With Durable Undercarriage Parts

In the world of hefty machinery and equipment, the function of undercarriage components is extremely important in guaranteeing ideal efficiency and long life. The efficiency and effectiveness of these components can substantially affect the total procedure of equipment, making the option of durable undercarriage parts an important decision for drivers and supervisors alike.

Benefits of Utilizing Resilient Undercarriage Parts

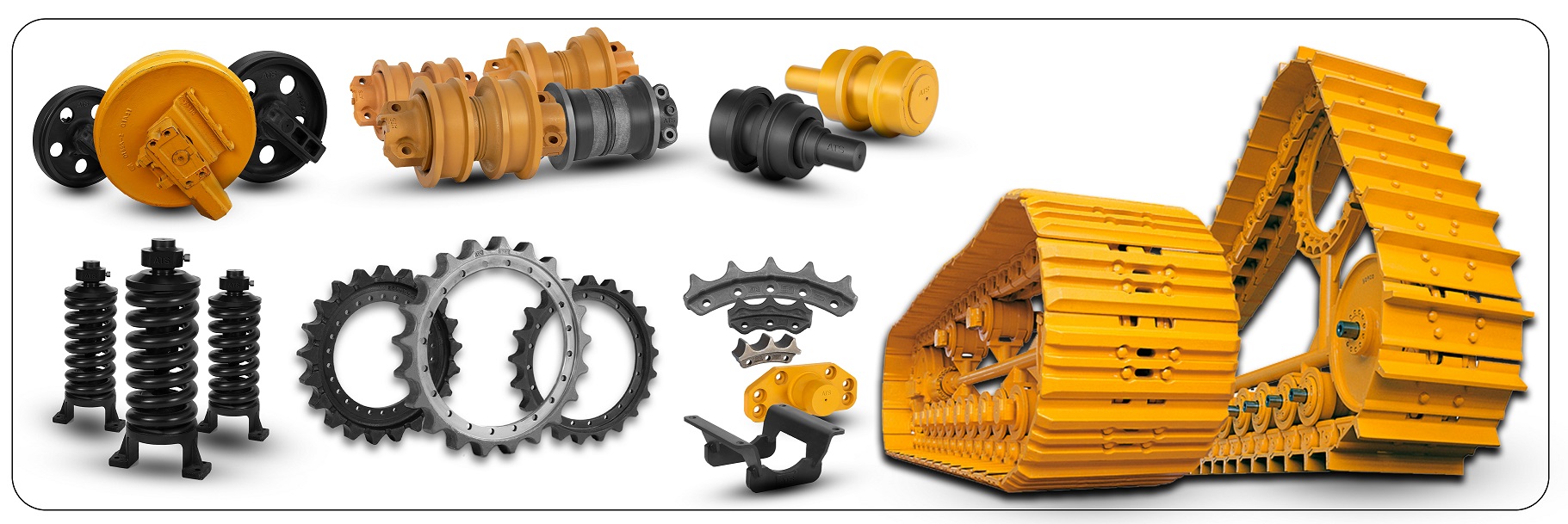

Using resilient undercarriage parts not only improves the durability of heavy machinery however additionally decreases maintenance expenses dramatically. By buying top notch undercarriage parts, such as tracks, idlers, rollers, and gears, tools drivers can experience raised uptime and boosted overall efficiency.

Additionally, the durability of hefty machinery is straight connected to the quality of its undercarriage parts. Long lasting components can stand up to the rigors of requiring applications, making certain that the devices remains functional for extended durations. Consequently, drivers can prevent costly downtime and upkeep expenses, eventually making best use of the roi for their equipment.

Factors Influencing Undercarriage Toughness

The resilience of undercarriage components in heavy machinery is influenced by different essential elements that directly effect performance and durability. One of the essential elements impacting undercarriage toughness is the top quality of products utilized in manufacturing. Premium materials, such as solidified steel, are important for standing up to the extreme conditions and heavy loads that undercarriage parts undergo. Correct upkeep techniques additionally play a critical duty in establishing the lifespan of undercarriage components. Routine assessments, lubrication, and prompt substitute of damaged components can substantially prolong the longevity of the undercarriage.

Moreover, ecological aspects can have a substantial effect on the durability of undercarriage parts. Direct exposure to rough products, severe temperatures, and rough working problems can speed up wear and tear on undercarriage parts. As a result, choosing undercarriage components that are especially created to stand up to these environmental challenges is crucial for making sure resilience.

In addition, the style and design of undercarriage parts have a direct impact on their resilience. Parts that are developed to disperse loads evenly, lower friction, and lessen tension concentrations are more most likely to have a much longer life expectancy - undercarriage parts. By taking into consideration these vital elements, tools drivers can take full advantage of the longevity and efficiency of their undercarriage parts

Maintenance Tips for Prolonging Undercarriage Life

Carrying out routine upkeep routines is vital for prolonging the life expectancy of undercarriage elements in heavy machinery. To lengthen the Clicking Here undercarriage life, it is critical to regularly evaluate for damage. Consistently look for absent or loosened screws, damaged rollers, or misaligned tracks, as these issues can intensify and cause further damage otherwise dealt with immediately. Furthermore, ensure that the undercarriage is properly oiled according to maker standards to minimize friction and stop premature wear.

Another essential maintenance tip is to maintain the undercarriage clean website here from dust, rocks, and debris. Accumulation in the undercarriage can accelerate wear and deterioration, resulting in pricey repair work. Washing the undercarriage after operation in rough conditions is advised to avoid these concerns.

Finally, monitoring and recording maintenance tasks can help in producing an aggressive maintenance timetable. Keeping in-depth records of inspections, repair services, and substitutes can offer beneficial insights right into the undercarriage's condition and performance with time, helping in forecasting and stopping potential failures. By adhering to these maintenance ideas diligently, operators can significantly increase the toughness and performance of undercarriage parts in heavy equipment.

Selecting the Right Undercarriage Elements

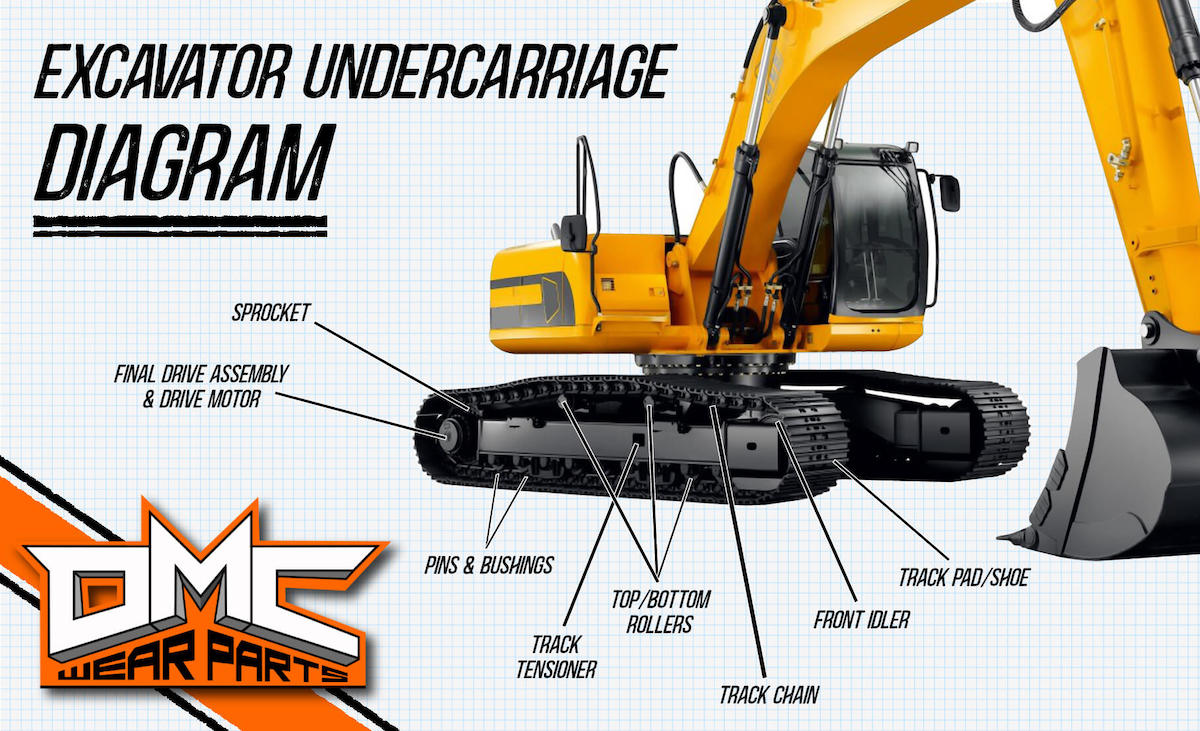

Picking proper undercarriage parts is important for making best use of the efficiency and durability of heavy equipment. When it concerns choosing the best undercarriage elements, there are several factors to think about. One essential aspect is comprehending the particular needs of the machine and the setting in which it will run. Various applications might require different kinds of undercarriage elements, such as tracks, idlers, sprockets, and rollers. It is click this link essential to pick elements that are created to endure the certain conditions the maker will certainly encounter, whether it be rough terrain, unpleasant products, or severe temperatures.

Opting for credible brand names known for creating high-performance and durable undercarriage parts can substantially influence the overall effectiveness and durability of the equipment. By meticulously selecting the ideal undercarriage parts, devices owners can enhance productivity, lower downtime, and prolong the lifespan of their hefty machinery.

Instance Studies: Improved Efficiency With Resilient Parts

Integrating long lasting undercarriage parts has actually demonstrated considerable improvements in equipment performance. One study involved a building and construction company that updated its excavator's undercarriage elements to more sturdy choices. The company observed a remarkable reduction in downtime due to undercarriage maintenance, causing boosted productivity and expense financial savings. The resilient components held up against harsh working problems, minimizing wear and tear substantially.

In an additional instance, a mining operation changed the undercarriage parts of its bulldozer with high-grade, durable options. This button brought about a remarkable enhancement in the excavator's ability to move and general efficiency. The machine could navigate difficult surfaces a lot more successfully, leading to improved operational effectiveness and lowered gas consumption.

Additionally, a logging business purchased resilient undercarriage components for its forestry devices. The updated parts exhibited extended life expectancy and boosted resistance to abrasion from harsh surface. The company experienced reduced upkeep prices and better tools uptime, inevitably enhancing its lower line. These situation research studies highlight the tangible benefits of making use of sturdy undercarriage components in enhancing equipment efficiency and long life.

Final Thought

Finally, utilizing sturdy undercarriage components can substantially enhance performance and longevity of hefty machinery. Elements such as correct upkeep and choosing the right parts play an important role in making best use of undercarriage durability. By applying these techniques, businesses can minimize downtime, increase performance, and ultimately reduce functional costs. Instance studies have actually shown that spending in durable undercarriage components can lead to enhanced overall efficiency and efficiency in numerous industries.

The performance and effectiveness of these elements can dramatically influence the general procedure of equipment, making the selection of durable undercarriage parts a vital choice for operators and managers alike.Integrating resilient undercarriage components has actually shown significant improvements in equipment efficiency. These case research studies highlight the substantial benefits of making use of resilient undercarriage components in maximizing equipment performance and longevity.

In conclusion, using long lasting undercarriage components can significantly improve performance and longevity of heavy equipment (undercarriage parts). Instance researches have actually shown that investing in resilient undercarriage parts can lead to improved overall performance and productivity in numerous sectors

Report this page